About metallic yarn

What’s the metallic yarn ?

Beginning of metallic yarn was guillotining(cutting) pure gold or pure silver foils which were adhered by lacquer on washi paper. It was especially spread in Japan because thin pure gold or silver foil and durable Japanese paper was developed. Production was started in Yamashiro & Joyo regions in Kyoto province. And it’s still major place of production there. Metallic yarn has different types by the difference of the shape. “Flat yarn” is the metallic yarn which is shaped only by the slit film, and “Supported yarn”, ”Twisted yarn” & ”round covered yarn” are twisted yarn which are twisted together with another fibers.

In the present day, aluminum or pure silver metallized Polyester film (or Nylon film) are widely used for the metallic yarn in place of pure gold or silver foil with washi paper. And now, it has been mass-produced and consumed for lots of applications called metallic yarn or lame’.

Original aluminum and pure silver metallized film is silver color, therefore if the film is coated by high transparency yellow ink, then it looks gold color. In a similar way, metallic blue color is made by silver color film & coating blue color ink on it.

Polyester and nylon films are thinner and soft and more durable than washi paper, therefore it can be slit thinner and longer, easier to manage and it is more reasonable. By these reasons, it’s major materials in the present day.

In earlier times, because of the use of precious metal and small production capacity, metallic yarn was used only for expensive cloths. On the other hand, in the present day, mass production became possible and it’s widely used for various applications such as ribbon & decoration for wrapping, casual shirt and sweater, socks, stockings, ethnic costume such as Japanese Kimono and so on all over the world.

Birth of metallic yarn

Initially in Japan, Metallic yarn was imported from China. And then, metallic yarn production was started in Japan but there is not identified in the record. In Japan, Metallic yarn was appeared in 6-8th century. The production was controlled by the government in Edo period in 17-19th century, and liberalization of sales started after Meiji period and then mas production was started in the present day.

In China, there is a description of the metallic yarn in Han period and it seems that both flat yarn and twisted yarn were existed in 6th century already.

In India, it seems that the metallic yarn was existed since ante-Christum. In the present day, it’s used a lot for the saree which is Indian ethnic cloth, and so on.

Also in Europe, metallic yarn was existed since ante-Christum and it was used for the luxury cloth for establishment & wealthy class such as baronage and kingly race, as the beginning.

Reference: Wikipedia Japan 「金銀糸 (Kinginshi)」、website of Nihon Kinginshi Kougyo Kyodo Kumiai

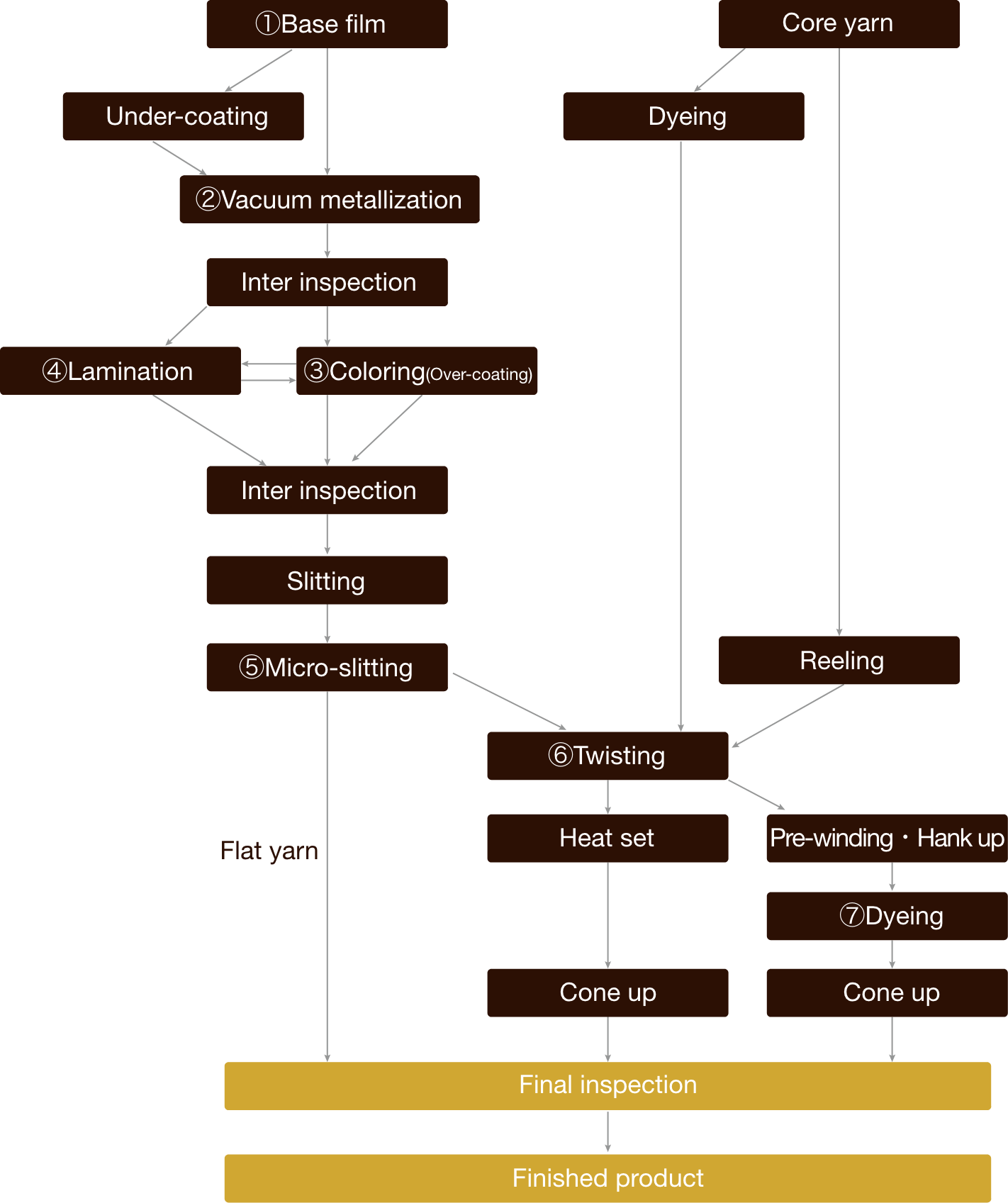

Flow chart of metallic yarn production

Deposition machine

Micro-slitter

Twisting

①Base film

Polyester film is used widely, but polyamide (nylon) film is also used sometimes for piece dyeing.

Japanese paper is still used partially.②Vacuum vapor deposition (Metallization)

It is a process of providing metallic luster by placing a thin metallic layer of silver, aluminum, tin or others on the base film. Inexpensive and steady luster aluminum deposition is common. Vacuum vapor deposition is a method of dissolving and evaporating metals at a high temperature in a vacuumed tank and applying metal atoms to paper, cloth, plastic film, lens, glass, etc. to form a metal coating. Currently it can do to film etc. continuously, in long length

③Coloring (Over-coating)

Although the metallized film itself has metallic luster, the metal layer can be easily peeled off and luster disappeared as it is. So, it can not be used. Therefore, protect the metal layer by coating the high transparency ink on the metal layer, or add color to the metal layer to make gold color or color metallic color. We will make various gold colors by coloring with various yellow ink on a silver metallized film.

④Lamination

Depending on the application, gold and silver yarns may be required for post-processability / dye resistance and high fastness. In order to obtain such high fastness, we will laminate various combinations of films, such as vapor deposited (metallized) film and polyester film, films after coloring, film vapor deposited and Japanese paper (washi), etc. according to the application. Recently, the nylon film which can be overdyed and the polyester film for the piece dyeing are always made by high quality 2PLY film by laminating.

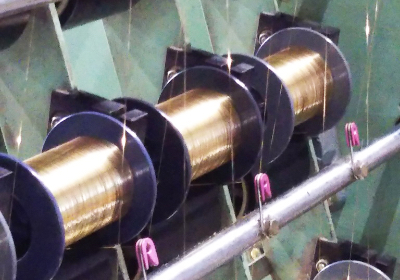

⑤Micro-slitting

First, colored and/or laminated films are cut to a width of 50 mm – 167 mm. The cut film is micro-slit by a micro slitter which is a cutting machine and slit the film to fine metallic yarn. This slit metallic yarn is called flat yarn (M-type).

Depending on the purpose such as texture and design, cut film is micro-slit from a minimum of 0.1 mm (1/254” inch) to a width of 3 mm (1/8” inch) and it’s wound into bobbin in one time. (As an image, while passing a cut film through a noodle cutting machine and it’s wound into bigger bobbins for the sewing machine. It is a spectacular view that fine metallic yarn is wound into 300-400 pieces of bobbins without breaking.

⑥Twisting

Flat yarn (metallic yarn) on bobbin is twisted with other fibers.

Twisting flat yarn with other filament yarns makes it stronger and hard to be broken. In addition, twisting with fibers makes a metallic yarn soft, better texture. It becomes a completely different thread by different twisting method & different fibers. Major twisting methods are described later.⑦Dyeing

By the technical innovation, we have developed the metallic yarn that can be over-dyeable or dye-resistant. Nowadays, we’ve produced over-dyeable yarns which are raw white silver & gold metallic yarns. And then, we dye our metallic yarns in package dyeing or in skein dyeing.

Compared to conventional metallic yarn which is colored by film coloring, we have much increased the color range (number of colors) and the delivery time became faster by introducing yarn dyed metallic yarn. In addition, special colors can be provided from a small quantity by this method.

Yarn dyed metallic yarn is higher in cost than conventional products, but many customers are pleased by its good fastness and formaldehyde free character. Approximately half of our inventory items are yarn dyed metallic yarn now.

Thickness and width of metallic yarn

Thickness

Thickness and slitting (cutting) width of film are important indication of the metallic yarn (lame’).

Average thickness of the hair of Japanese is 80μ(0.08mm).

General thickness of copy paper is 90μ (0.09mm).

Kitchen wrap is 11μ(0.011mm).

| Micron (μ) | Gauge | mm |

|---|---|---|

| 6 micron | 25 GAUGE | 0.006mm |

| 12 micron | 50 GAUGE | 0.012mm |

| 25 micron | 100 GAUGE | 0.025mm |

| 38 micron | 150 GAUGE | 0.038mm |

| 50 micron | 200 GAUGE | 0.05mm |

・・・Standard product

Slitting width (Cutting width)

Elastic band is 1.1mm (1/23”).

Mechanical pencil lead is 0.5mm (1/50”).

Our thinnest and finest metallic yarn (film) is 12μthickness & 0.1mm (1/254”) width.

It’s similar to cut the kitchen wrap to the width of the hair of Japanese.

Metallic yarn is slit to following width mainly.

| Metric | Inch |

|---|---|

| 0.10mm | 1/254” |

| 0.12mm | 1/210” |

| 0.15mm | 1/168” |

| 0.20mm | 1/127” |

| 0.23mm | 1/110” |

| 0.25mm | 1/100” |

| 0.27mm | 1/92” |

| 0.30mm | 1/85” |

| 0.33mm | 1/75” |

| 0.37mm | 1/69” |

| 0.40mm | 1/64” |

| 0.5mm | 1/50” |

| 0.6mm | 1/43” |

| 0.75mm | 1/32” |

| 1.5mm | 1/16” |

| 3.0mm | 1/8” |

Shapes of metallic yarn and twisting method

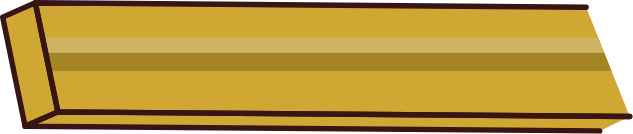

Flat yarn

Flat yarn which the film roll is slit and called “slit yarn”, “unsupported yarn”.Usually it’s wound on the flanged bobbins. It has high luster, but it’s broken or stretched in some uses.It’s used often for warp of weaving and fancy yarn making.

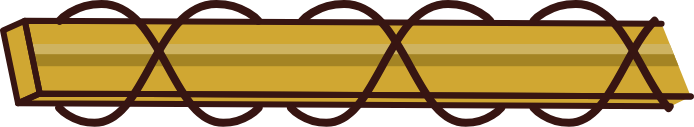

Supported yarn

Flat yarn is supported by 2 ends nylon yarns. Nylon yarns support (cover) the metallic yarn by X shape (S direction & Z direction). It’s stronger and easier to use than the flat yarn and widely used for weft of weaving and circular knitting often.

Twisted yarn (Hagoromo)

Flat yarn (metallic yarn part) is twisted roughly with the core yarn. It glitters well and well used for flat-bed knitting.

Round covered yarn (Gimp yarn)

Metallic yarn is round-covered fully on core yarn. Metallic yarn part hides the core yarn completely. It’s used for embroidery, Weaving, Japanese Kimono item and so on.

Jabara (Space twisted yarn)

Metallic yarn is round-covered evenly with some space to show the core yarn. Core yarn can be seen with metallic and its color and appearance are interesting.

3 ends twisted yarn (Bri-yarn)

Twisted yarn (Hagoromo) as mentioned above, supported by another thin yarn in reverse direction for easy use and avoid yarn breaks. It glitters well like twisted yarn (Hagoromo)

In addition, we are always developing and will launch new yarns by twisting kinds of metallic yarns with kinds of filaments, thread, fancy yarns by modifying and changing a twisting method and so on.